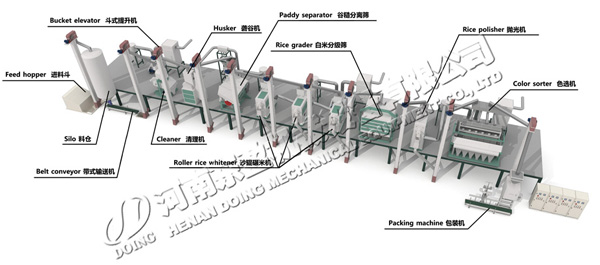

The main steps of the rice mill process

FAQ / Chat online / Technical support / Apr 09, 2019

What are the main steps in the rice mill process, Doing Company as the rice mill equipment manufacturers are introduced as follows:

1. Pre-cleaning: Remove all impurities in rice and grains without rice.

2. Go to the stone: Separate the small stone from the rice.

3. Hulling: Remove the rice husk.

Processing paddy into white rice

Processing paddy into white rice

4. Crust vacuum: Separate the chaff from the brown rice.

5. Rice separation: Separate unhulled rice from brown rice.

6. Whitening: Remove bran and germ from brown rice to obtain white rice.

7. Polishing: Improves the appearance of the rice grain by removing the remaining bran particles and polishing the surface of the rice grain.

8. Rice grading: Separate broken rice to obtain high quality rice products from the rice mill process.

Roller rice whitener

Roller rice whitener

In the case of continuous processing and improvement of rice mill process technology and equipment, combined with the specific regulations and requirements for quality management in rice mill process, in view of the quality control in the processing of rice, the preparation of raw grain storage, preparation before processing, supervision during product processing, and finished products Dynamic management of key control points such as inspection and finished product storage to improve the quality of rice processing.

Complete rice mill process

Complete rice mill process

The rice mill process effective management of key control points is the focus of rice processing and the key to ensuring high quality rice. The specific regulatory methods for the rice mill process are as follows:

1. Rice cleaning and grading: According to the impurity content of the original grain, multi-channel screening and multi-channel stone removal are used to ensure the quality of the net. At the end of the cleaning process, the rice is classified according to the size of the grain, and the common equipment is stone removing machine.

2. Back to the husking processing and brown rice processing: reducing the rough broken rice, bursting waist is the main task of this control point. In the rice mill process, if the brown rice has a low water content, the brown rice can be atomized to reduce the whitening pressure and increase the rice yield.

Large capacity rice mill plant

Large capacity rice mill plant

3. Multi-channel rice milling and rice polishing: Multi-channel rice milling can reduce broken rice, increase rice yield, greatly reduce the unevenness of rough white, and rice polishing is an indispensable procedure for producing high-quality rice in the rice mill process. It also helps preserve the freshness of rice.

4. Whitening and polishing design: set according to the characteristics, grade and quality requirements of the finished product. Reasonable rice mill process has 3 whitening and 1 polishing.