How to choose a complete rice processing equipment manufacturer?

FAQ / Chat online / Technical support / Mar 20, 2019

Rice is the most widely accepted staple food in the world, and the number of people who eat rice in the world is also increasing. Rice's embryo and aleurone layer contain nearly 64% of rice nutrients and more than 90% of the nutrients required by the human body. Therefore, rice processing is of great significance. With the development of the rice processing industry, rice processing equipment have now entered a modern production mode. Modern rice processing equipment have replaced manual production with rice processing equipment as the main processing method. Since rice processing machinery has an important impact on the economics of rice plants, the choice of rice processing equipment manufacturers is very important. But how to choose a rice processing equipment manufacturer? Here are five suggestions for your reference.

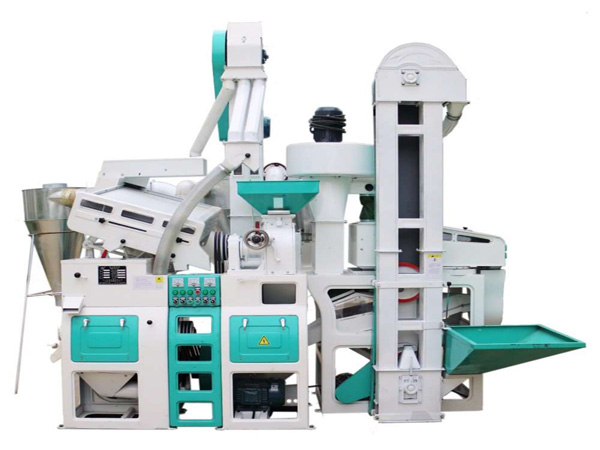

Rice processing equipment

1.Investigate reputation and production qualifications of supplier

The reputation of the rice processing equipment manufacturers is very important. The evaluation of buyers will be more realistic, and product quality and technology will be more secure.

At the same time, production qualifications are also very important. There are many manufacturers of rice processing equipment on the market, but not all of them have production qualifications. In order to obtain benefits, some manufacturers produce them privately, and the quality is difficult to guarantee, which is easy to cause losses to the purchaser. Therefore, to select rice processing equipment manufacturers, we must investigate their reputation and production qualifications.

2.Consider whether the equipment output matches your needs

Buyers should consider how much rice production equipment they need, the power requirements, whether they need polishing machines, color sorters, and other further processing equipment. Some manufacturers mainly produce large-scale equipment, some manufacturers mainly produce small equipment, and some provide complete equipment including polishing machine and color sorting machine. These factors must be taken into account.

Complete rice processing equipment

3.Field survey equipment operation status

After all, the customer's main concern is the raw material processing capacity and actual consumption data of the complete rice processing machinery. Most of them can be seen on the official website of the rice processing equipment manufacturer.

However, users with conditions should try to visit the equipment in the production factory of rice processing equipment, and personally understand the operation of the equipment, actual processing capacity, investment and benefit comparison. Technicians can also more intuitively understand the equipment operating conditions and process technology, which will be more helpful for the subsequent operation of the equipment.

4.Look at the price of the equipment

The performance of different rice processing equipment is different, the capacity is different, the power is different, so the price is different. The user must select the rice processing machine manufacturer according to the actual processing volume of the individual, and select the most cost-effective equipment within the investment budget or customize the equipment that suits him or her.

Processed rice

5.Consider the pre-sales and after-sales service

Adequate market research must be conducted before selecting a rice processing machine manufacturer. It is necessary to know whether the manufacturer's installation and commissioning are strict, whether the technical guidance and training are professional, whether the after-sales service is timely, and whether the spare parts supply is sufficient. A truly powerful manufacturer of rice processing machinery will provide tailor-made solutions for users. Such as on-site inspection, equipment selection guidance, production line layout planning, old factory upgrades, plant surveying and mapping design, operational technology training, equipment site installation guidance.

Doing Machinery is a professional manufacturer of advanced rice processing equipment with independent research and development and professional design and production experience. The key components of rice processing machinery are imported from Europe, with high performance, high quality, low energy consumption and low price. With a complete pre-sale, sale, and after-sales service system, we can not only build after-sales customer files for customers, but also provide online customer service to track and receive customer feedback in a timely manner. In addition, DOING provides customers with troubleshooting, equipment maintenance, upgrades and other professional services.

Prev: The End!