New rice polishing machine with high technology

Industry News / Chat online / Technical support / Mar 20, 2019

The working process of the rice polishing machine is as follows: the white rice which has been calibrated by the rice milling machine and reaches the standard of one meter is flowed from the feeding port into the polishing chamber, and the heated water passes through the flowmeter Through the temperature-controlled water tank, and flows through the rubber tube. The gas-water mixture nozzle forms a water mist through the high-pressure air and enters the water-cooling zone of the hollow main shaft. Pressure suction, the water mist passes through the vent hole of the main shaft and the polishing roller and enters the surface of the polishing roller to mix with the rice and adheres.

Polisher

On the surface of the rice grains, the surface of the rice grains is moistened and softened. By rotating the rotary motion of the indoor polishing roller, the rice grains are constantly moved in the polishing chamber, and during the movement, relative movement, relative friction and extrusion are generated between the rice grains, between the rice grains and the polishing rolls, and between the rice grains and the rice sieves. On the other hand, during the friction extrusion process, the starch layer on the surface of the white rice is pasted and crystallized to form a bright protective film, which improves the surface finish and prolongs the storage time of the The fine rice bran and fines produced during the polishing process are removed from the machine through the rice sieve hole under the action of negative pressure and strong suction.

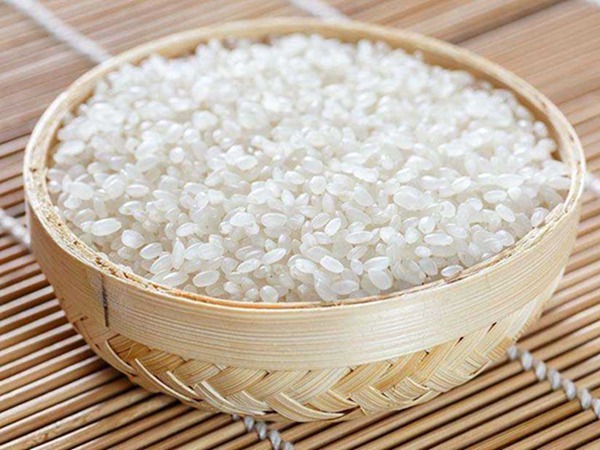

Polished rice

The treatment of the surface of the rice grain makes the rice grain crystal clear and forms a very thin gel film on the surface of the rice grain. This process is called polishing. The main function of the rice polishing machine is to remove the tantalum powder adhering to the surface of the white rice. After the surface of the rice is glazed, there is a layer of waxy protective layer, which not only prevents the rice from sticking or the rice flour falling off in the production, storage, transportation and sales, ensuring the cleanliness of the rice, and improving the quality and commodity value of the finished rice. It is conducive to the storage of rice, maintains the freshness of rice, and improves the eating quality of rice.

And unlike traditional polishing machines, the new polishing machine can reduce the generation of broken rice.