Rice processing technology

Industry News / Chat online / Technical support / May 23, 2019

Rice is one of the most important staple food, and raw paddy is widely grown around the world. Therefore, rice processing technology plays an important role in crops production industry, which can directly affect finished rice quality.

Rice processing technology mainly reflects in rice milling process and parboiled rice process.

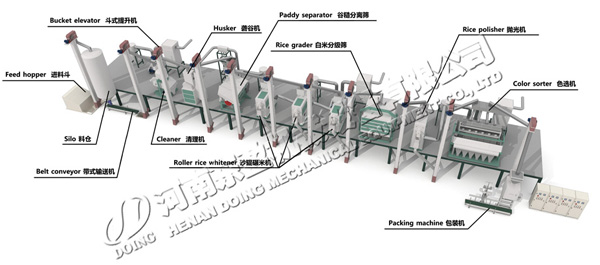

Rice mill production process

Rice mill production process

Most of rice that we eat in our daily life is produced from paddy, which is cleaned, husked, milled, polished, etc. and finally get edible rice. Many years ago, people need to produce rice from paddy with hand and basic original tools, working efficiency is slow and rice quality is bad. Nowadays rice processing technology makes the whole process easier, which improves working efficiency as well as finished rice quality. Machines like cleaner, de-stoner, husker, paddy separator, polisher, color sorter and rice grader etc. were invented to meet people's requirements for different purpose and different steps. In big scale rice production factory, all these rice equipment can be connected with various size of elevators, which makes the whole production line automatic and contentious.

Apart from rice milling, rice processing technology has been well applied in the processing of parboiled rice.

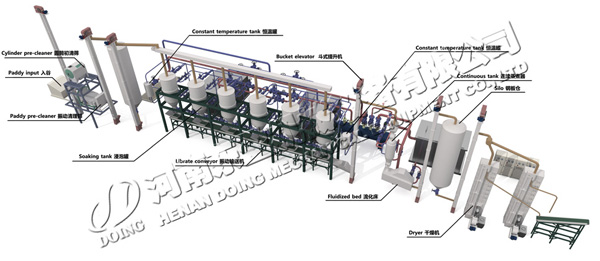

Parboiled paddy processing

Parboiled paddy processing

Parboiled rice is commonly known as “semi-cooked rice”. It is produced by raw paddy, which is cleaned, soaked, steamed, dried, etc., and then processed according to conventional rice milling process. It has the characteristics of high nutritional value, high rice yield, high oil yield, long storage period and short cooking time. With increasing demand in Africa market, parboiling rice processing technology has been gradually improved and developed.

Parboiled rice processing technology is mainly applied in five processing sections: raw paddy cleaning, soaking, steaming, drying and milling. Every machine is special designed based on parboiled rice processing procedures. For better running of equipment, distribution box is furnished to control and monitor status of every machine. Besides various pipeline connections ensure continuous processing of rice and guarantee a cleaner working environment.

Whether in rice milling process or parboiled rice process, rice processing technology never stops developing. Our engineer team will keep working hard and provide you best solutions for rice production.