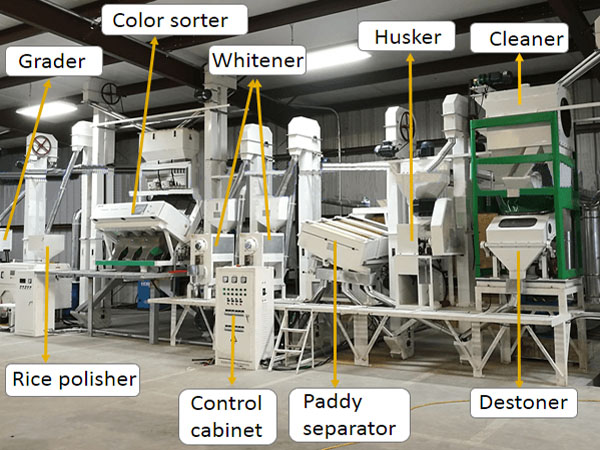

Rice mill plant machinery

Industry News / Chat online / Technical support / May 27, 2019

People are inclined to mechanical processing for rice milling, so there is more and more rice mill plant machinery in the world. When you choose to invest in rice mill plant machinery, the focus is on whether the machine technology can maximum capacity and optimum quality are achieved.

Rice mill plant machinery is a new design concept in the development of millet products industry. It adopts a very advanced production process and completely solves the problem that the traditional process of shell hard milling is easy to crush and unevenly milled. The rice processing equipment adopts the steel frame platform, which has the advantages of compact structure, simple installation, advanced technology, compact combination, the high rice yield, crystal clear, and no powder. The rice mill plant machinery can be applicable to different regions and the variety of rice processing raw grain is both beautiful and convenient for operation and maintenance.

Rice mill plant machines

Rice mill plant machines

When you order rice mill plant machinery, you first need to realise the process and characteristics of the fully automatic household rice mill equipment, the system settings and the role of each system, and master how to achieve better rice milling effect. Secondly, it is necessary to familiarize with the main structure and function of the complete set of automatic rice milling machine, the operation precautions and methods in the production process, especially the parts closely related to the grinding effect, and then memorize the technical parameters of the grinding rollers of each system. Then let’s see the two main machine of rice mill plant machinery.

Doing Company rice mill machines

Doing Company rice mill machines

First, the vibration cleaning screen:

1. This machine can be used for the initial cleaning of various food, and the cleaning effect is good.

2. The use of vibration motor drive, combined support springs to ensure the stability of vibration.

3. Using innovative technology, the flow rate of the material in the lower part of the screen surface is reduced to achieve a better cleaning effect.

4. Fast screen surface is pressing mechanism, easy to install and remove the screen surface.

5. A variety of screen sizes are available to meet the need of different food cleaning.

Second, rice husking machine and separator:

1. The shelling rate is high and stable. The machine adopts automatic control operation, and the shelling rate is about 90%.

2.The operation is convenient to adjust, the machine controls the pressure between the rollers pneumatically, and the material position device is connected with it. The material can be loosened immediately, and the material is automatically delayed by the tension roller.

3. The operation is stable. The main rotating parts of the machine are tested by dynamic balance, so the operation is stable and the vibration is small. You are welcome to consult if you want to know more about rice mill plant machinery.