Parboiled rice production line

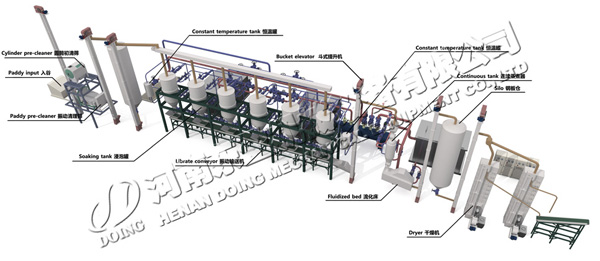

After the cleaned paddy is hydrothermally treated, the finished rice obtained from the husking process and whitening process is called parboiled rice. DOING manufactured parboiled rice production line for sale based on the current mature technology, Doing Company adopts a simpler method to clean, wash, infiltrate and cook the rice, which effectively shortens the time of the water treatment in the original process and makes the parboiled rice production line production more continuous, higher efficiency.

In the parboiled rice production line, the processing mainly divided into two parts:

1. Paddy— Pre-cleaning— Clean and destone— Soaking— Cooking— Send into the dryer

Parboiled rice production line

Parboiled rice production line

Soaking process: Adopt the high-temperature immersion method which widely used all over the world, and the water is fully absorbed by paddy in a short time by vacuuming, constant temperature and pressurized immersion, make the water content of rice is more than 30%, which is a necessary condition for the full gelatinization of rice starch in the cooking process. In the parboiled rice production line, this processing section is basic and important.

Soaking tank

Soaking tank

Cooking process: High-pressure high-temperature steam is adopted, and the steaming temperature, time, uniformity, etc. must be strictly controlled, so that the starch in the rice can reach full but not excessive gelatinization. Only when the starch is fully gelatinized, the finished parboiled rice produced in the parboiled rice production line color is transparent and honey color.

Drying process: using the heat of the boiler, converting it into hot air through a heat exchanger, indirectly drying the rice, and the dried rice has no pollution and no odor. Drying is divided into two stages, one is divided into rapid drying, and the second is slow drying, its a rice that is fully slowed down, reducing the rate of crushing and increasing the rate of whole rice.

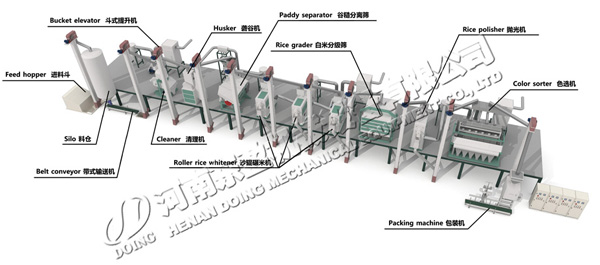

2. Rice milling process: steamed rice — destone — husking — separation — whitening — polishing — color sorter — package — finished parboiled rice into the warehouse

Rice mill process

Rice mill process

That's to say, in the parboiled rice production line, except the starting soaking and cooking process and the like, further production process is similiar as the normal rice processing.

Below is the main equipments design and manufactured by Doing Company used in the parboiled rice production line:

| No. | Name | Capacity(t/h) | Power |

| 1 | Rotary pre-cleaner | 20-35 | 0.6-0.75 |

| 2 | Vibration cleaner | 10 | 0.75 |

| 3 | Suction type destoner | 8-9 | 0.3*2 |

| 4 | Magnetic separator | 10 | 1.5 |

| 5 | Cooker | 10-15 | 11 |

| 6 | Continuous tower dryer | 30 | 22 |

| 7 | Husker | 5-6 | 5.5*2 |

| 8 | Paddy separator | 5.5-6.5 | 4 |

| 9 | Vertical sand roller type rice mill | 4-5 | 37-45 |

| 10 | Vertical iron roller rice mill | 4-5 | 37-45 |

| 11 | Rice grader | 4-5 | 0.75 |

| 12 | Color sorter | 3-4 | 0.75 |

| 13 | Polisher | 3-5 | 7.5 |

| 14 | Automatic packing machine | 5-50kgs | 11 |

Note: This is only the equipment needed for some of the main steamed rice production lines. The specific machine configuration needs to be finalized according to your requirements and technicians.

Prev: Parboiled rice equipment

Next: The End!