Parboiled rice equipment

Parboiled system introduction:

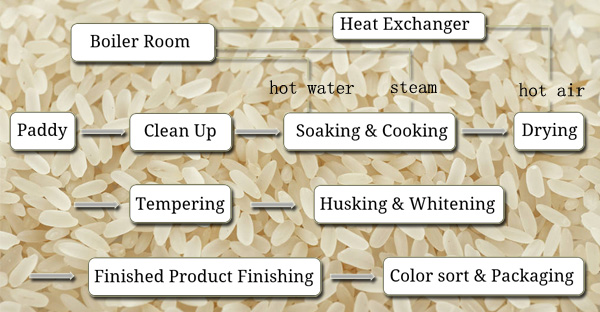

The production process of parboiled rice generally includes: pre-cleaning, soaking, steaming, hulling, rice milling, and the like. The parboiled system includes: pre-cleaning, soaking, steaming and drying. Pre-cleaning generally uses vibration cleaning screens or plane rotary cleaning screens, stone removing machines and other equipment to remove large, medium and small impurities and stones in the paddy to obtain clean paddy and enter the subsequent process.

The selection principle of parboiled rice equipment: mainly based on output and power. Before the operation of the hulling process, the output of the equipment needs to be greater than the hourly output. If there is not enough, the two units are connected in parallel. In the case of consistent output, the parboiled rice equipment with lower power is adopted.

Parboiled rice production process

Parboiled rice production process

Next, Doing Company will introduce you to the main machines of parboiled rice equipment.

1. Paddy pre-cleaner:

The pre-cleaner can effectively remove large debris such as wheat-straw, straw, stone, and twine mixed into rice, effectively avoiding the failure of downstream processing equipment or damage of parts, this part is the firtly process of parboiled rice equipment. The utility model pre-cleaner has the advantages of good cleaning effect, simple structure, convenient operation, stable operation, small occupied area, small power consumption, convenient replacement of the screen cylinder and maintenance.

2. Suction-type specific gravity de-stoner

The suction type stone removing machine uses the difference of the grain weight and the impurity specific gravity and the suspension speed to carry out the separation of the grains. Mainly used for grain cleaning and seed selection in wheat, rice, corn, etc. It is under negative pressure during work, clean and hygienic, and free of dust. The device is mainly composed of a feeding device, a stone removing device, a supporting mechanism and a vibration motor. The machine with features of self-balance of the screen body, stable and reliable operation, low noise and low power consumption. The structure is exquisite and the cleaning effect is good. Especially for clearing the alongside stone, the stone remove efficiency can reach 99%.

Parboiled rice equipment

Parboiled rice equipment

3. Permanent magnetic cylinder magnetic separator:

The permanent magnet cartridge magnetic separator is a magnetic separation device that continuously removes iron from dry material and is widely used in the grain processing industry. The inside of the equipment adopts a unique magnetic furnace design, which is made of high-quality ferrite material or composited with rare earth magnetic steel. The average magnetic induction intensity of the cylinder table is high, the magnetic field is strong, the suction is large, the iron removal rate is high, maintenance-free, energy saving and use. Safe and reliable, it can adjust the control feed amount and is suitable for parboiled rice equipment requirements.

4. Boiler system, soaking tank:

The soaking process is to feed the cleaned and graded rice into a tank-shaped pressure vessel, and an air valve is arranged on the upper part of the pressure vessel to ensure that the valve is closed after the rice enters, and the container is closed, and the lower part of the pressure vessel is provided with a rotary discharge valve to ensure The pressure inside the container during the discharge process is constant. When the rice enters the pressure vessel, the vacuum system is activated to extract some of the air in the tank, reducing the gap between the rice, which can increase the loading of the rice and reduce the water for soaking. After the vacuuming is completed, hot water of a certain temperature is injected into the container and pressurized. In the soaking process, we use the hot water circulation system to ensure the water temperature at all points in the container is consistent, and use the high temperature steam provided by the boiler system to exchange heat with the circulating water to compensate for the heat lost during the parboiled rice equipment soaking process.

Boiler

Boiler

5. Cooking machine:

The cooking process must be carried out in batches during the parboiled rice equipment processing. The rice and the soaking liquid are separated first, and the rice with a moisture content of about 40% is sent to the digester by means of a vibrating conveying device, the container is sealed, and then a saturated vapor of 120 degrees Celsius is introduced, then the starch in the endosperm portion of the rice is rapidly gelatinized.

6. Continuous tower dryer:

The initially dried rice is passed through a continuous tower dryer. The hot air temperature of the tower dryer is about 60 degrees Celsius, which can continue to reduce the moisture of the rice and take away the heat of the rice, reduce the temperature of the rice, and reduce the water to about 18%. At this time, the rice with water content of about 18% is placed in the temporary storage bin with the ventilation system for 8-12 h according to the quality of the original grain, so that the moisture and temperature inside and outside the rice tend to be homogenized, and the surface temperature of the rice is lowered. The low-temperature slow-speed batch-type tower dryer is used to reduce the combined water of rice.

Low temperature dryer

Low temperature dryer

7. Hulling Machine:

The hulling process adopts a rubber roller glutinous rice machine, and the main working member is a pair of juxtaposed and elastic rubber rollers. The two rubber rollers rotate in opposite directions at different speeds, and the rice enters between the two rollers and is pressed, rubbed and rubbed by the rubber roller and other effects to make the rice husk destruction and brown rice separation. Since the rubber roller is an elastic body and is not easy to damage the rice grain, the rubber roller mill has the characteristics of high shelling rate, low crushing rate and large output.

8. Suction separator (rice shell separator):

The suction separator is specially used to separate low-specific gravity impurities such as chaff and dust from the rice. Its biggest feature is: large suction area, good wind and good wind selection.

Paddy separator

Paddy separator

9. Paddy and brown rice separation sieve:

The paddy and brown rice separation sieve is a coarse separation equipment widely used in parboiled rice equipment. The utility model has the advantages of compact structure, small occupied area, short screening process, high screening efficiency and simple operation management. The grain coarse separation flat screen mainly consists of a feeding device, a sieve body, a screen tilt angle adjusting mechanism, an eccentric rotating mechanism, a transmission and a speed regulating mechanism, and a frame. The inside of the sieve body is equipped with three drawer type sieve grids, and 1/3 of the front surface of each sieve layer is a graded section, and the classification is realized by mesh hole encryption to ensure that the brown rice is well graded automatically before perforation; There is a collecting plate, which guides the undersize to the feeding end of the lower sieve surface to ensure the thickness of the material on the sieve and promote the automatic classification of the material.

10. Vertical sand roller rice milling machine:

The rice milling machine designed and manufactured by Doing Company adopts the two-way rice milling process of sand roller and iron roller. The sand roller rice mill removes the outer layer of rice by the grinding between the rotating sand roller and the brown rice. The rice processed by the milling rice mill has a very white appearance and a slightly rough surface, whitening process. The iron roller is used for rubbing away from whitening, and the whitening pressure is large, and the pressure can be used for rubbing rice and polishing. In addition, the iron roller rice mill also has a humidifying device, which can soften the residual rice bran skin layer by using the atomized water of the whitening chamber, reduce the working temperature of the whitening chamber, and can produce high quality rice. The sand roller rice milling machine is an important part, not only for complete parboiled rice equipment, also for normal rice mill plant.

Roller rice mill machine

Roller rice mill machine

The basic principle of the sand roller rice milling machine is: when the brown rice enters the rice milling machine from the feeding hopper, it is spirally driven by the rotating roller. The rice grains are rubbed by the various parts in the whitening chamber and their mutual friction. When the frictional force overcomes the coupling force between the rice grain layer and the endosperm, the skin layer and the endosperm will slip, causing the skin layer to extend and break and fall off. As the volume of the whitening chamber is gradually reduced, the density between the rice grains is increased, and the pressing force in the whitening chamber is increased. In addition, the roller is continuously turned over and pushed forward, so that the rice grains are further whitened, and the rice grains after the whitening are The rice mouth is discharged, and the swarf is discharged by the rice sieve and the dust collector.

11. White rice grader:

The white rice grader is equipped with two drawer type sieves, which are divided into front and rear sections. The sieve on the first sieve is special pole rice, the sieve hole is generally 3.2-3.7 mm; the latter section is generally 3.0-3.5 mm. The undersize is dropped through the bottom plate into the front screen of the second layer. The sieve material passes through a sieve hole having a large diameter, and the sieve mesh hole is generally 2.0-2.2 mb. Due to automatic classification, the small broken rice quickly sinks and contacts with the sieve hole to become a sieve material, and the sieve meshes into the rear sieve surface. The sieve hole used is 2.6-2.8 mm, and the sieve is a large rice. The advantages of the DOING white rice grader are: a large plane rotary motion can accurately separate the special rice, the general rice, the large broken rice, the small broken rice; the feeding mechanism is adjusted by the pressure door, and the feeding is uniform; the front suction device can Effectively reduce the temperature of rice, easy to operate and easy to maintain.

Large capacity rice grader

Large capacity rice grader

12. Color sorter:

The color selection is sorted by using different color differences between materials, and is composed of a feeding hopper, a vibrating feeder, a chute channel, a photoelectric sorting box, a discharging hopper, a bucket elevator and an electric control box. When the material passes through the vibrating feeding system and passes through the chute (or straight) channel evenly into the sorting area (electron optical analyzer), both sides of the material are probed by the photodetector. The photodetector will measure the intensity of the reflected light from the material and compare it to the intensity of the reflected light from the standard swatch. The color sorting machine amplifies the light intensity difference signal, and when the signal is greater than the predetermined value, drives the electronic airflow injection valve to blow the rice which is not good enough out.

13. Polishing machine:

The white rice polishing machine is the main equipment for the processing of polished rice for the parboiled rice equipment, and is the key equipment for the production of rice-free rice. The equipment is a new product developed on the basis of combining the advantages of similar foreign models. It is characterized by reasonable structure, simple operation, good process effect and low energy consumption. The machine is mainly composed of a feeding device, a spray chamber or an atomization control box, a polishing chamber, a spray system, a frame, a spray nozzle and the like. The operation method is basically similar to that of the rice milling machine, except that an atomization system is added.

Parboiled rice production machine

Parboiled rice production machine

Characteristics of parboiled rice:

After the hydrothermal treatment of the steamed valley system, the rice has significant characteristics different from ordinary rice during processing:

(1) The pre-cleaning and soaking water washing effect makes the steamed rice have lower impurity content than ordinary rice and is easy to clean.

(2) The parboiled rice equipment's thermal expansion and contraction process of hydrothermal treatment reduces the knot and strength of rice husks and is easy to hulling.

(3) Hydrothermal treatment increases the adhesion between the enamel layer and the rice endosperm, and increases the difficulty of the steaming rice milling process.

(4) The hydrothermal treatment changes the color of the rice grains and increases the difficulty of the color selection process, but adopt DOING professional parboiled rice equipment, this part is no need to worry.

(5) Hydrothermal treatment changes the internal stress of steamed rice, and it needs to be slowed down before further processing.

Complete rice mill

Complete rice mill

The clean rice is subjected to hydrothermal treatment such as soaking, steaming, drying, etc., and the obtained product is steamed rice, and the steamed rice is processed by steaming rice and rice milling to produce steamed rice. Parboiled rice has the characteristics of high nutritional value, easy digestion, high rice yield, short cooking time and storage resistance.

Parboiled rice is very popular in Africa, Europe, America and the Middle East. About 25% of the rice in international trade is steamed rice. If you plan to start a business of the parboiled rice production, Doing Company can design and manufacture parboiled rice equipment with different production and configuration requirements according to your requirements.

Prev: The End!