How to produce rice in high quality?

FAQ / Chat online / Technical support / May 16, 2019

As a main source of nourishment for over half the world's population, rice is by far one of the most important commercial food crops. Its annual yield worldwide is approximately 535 million tons. Over 300 million acres of Asian land is used for growing rice. Rice production is so important to Asian cultures that oftentimes the word for rice in a particular Asian language also means food itself. With people’s higher requirement , How to produce rice in high quality will be the trend in future.

Harvest

Harvest

There are some factors will affect how to produce rice in high quality:

1. The rice variety

The most suitable variety is the one best meeting farmer’s and consumer’s needs. Rice Varieties should be selected based on good yield potential, resistance to disease, good eating qualities, high milling yield, and are suitable for the market.

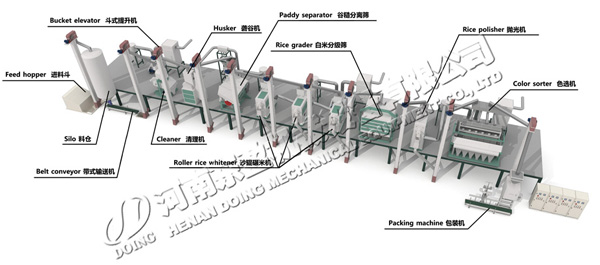

Rice milling process designed by Doing Company

Rice milling process designed by Doing Company

2. The management from planting to harvesting

2.1 Planting rice on time . Planting the crop on time will help produce a fast-growing, uniform crop that will have higher yields and will be better able to compete with weeds and pests.The best time to plant depends on the locality, variety, water availability, and the best harvest time.

2.2 Weed early.Weeds compete directly with the rice plants and reduce rice yield. Each 1 kg dry matter of weeds is equivalent to 1 kg grain loss. Weeds cause most yield loss within the first 20–50 days after crop establishment.

2.3 Fertilize to maximize returns. Most soils provide only limited amount of nutrients to the crop, therefore fertilizers need to be applied to increase grain yield. According to different soil, add different fertilizer.

2.4 Use water efficiently.Water availability largely determines the potential crop yield. For a crop to continue to grow, the water supply needs to be similar or a little above evaporation. Good water control increases crop yields and grain quality as well as improving the efficiency of other inputs such as fertilizer, herbicide, and pesticides.

Rice mill

Rice mill

2.5 Control pests and diseases effectively. In addition to good crop management, timely and accurate diagnosis can significantly reduce losses.The best control for pests and disease problems is prevention.

2.6 Harvesting rice on time. Once the plants have reached full growth (approximately three months after planting) and the grains begin to ripen—the tops begin to droop and the stem yellows—the water is drained from the fields. As the fields dry, the grains ripen further and harvesting is commenced.

2.7 Drying: Before milling, rice grains must be dried in order to decrease the moisture content to between 18-22%. This is done with artificially heated air or, more often, with the help of naturally occurring sunshine. Rice grains are left on racks in fields to dry out naturally. Once dried, the rice grain, now called rough rice, is ready for processing.

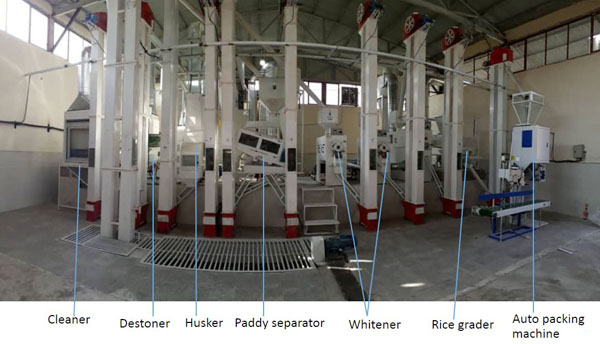

Large rice mill factory

Large rice mill factory

3. Choosing good rice milling plant will effect how to produce rice in high quality

A good and suitable milling plant will reduce the broken rice rate, clean the paddy completely, and polishing the rice better etc.

3.1 Hulling can be done by hand by rolling or grinding the rough rice between stones. However, more often it is processed at a mill with the help of automated processes. The rough rice is first cleaned by passing through a number of sieves that sift out the debris. Blown air removes top matter.

3.2 From the shelling machine, the grains and hulls are conveyed to a stone reel that aspirates the waste hulls and moves the kernels to a machine that separates the hulled from the unhulled grains. By shaking the kernels, the paddy machine forces the heavier unhulled grains to one side of the machine, while the lighter weight rice falls to the other end. The unhulled grains are then siphoned to another batch of shelling machines to complete the hulling process. Hulled rice grains are known as brown rice.

Main rice mill machine

Main rice mill machine

3.3 Milling . Since it retains the outer bran layers of the rice grain, brown rice needs no other processing. However along with added vitamins and minerals, the bran layers also contain oil that makes brown rice spoil faster than milled white rice. That is one of the reasons why brown rice is milled further to create a more visually appealing white rice.

3.4 Polishing: polishing will make the rice more white and sell good price in market

3.5 Grading: Choose correct rice mill and grading machine to separate the brown rice, broken rice and white rice

3.6 Sorting and packaging finally.

After reading this article, we hope it will help you learn more knowledge about how to produce rice in high quality, and learn more about rice milling machine etc. If you have any requirement about rice mill, please contact our company directly.