How rice milling machine work?

FAQ / Chat online / Technical support / May 22, 2019

The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled, free of impurities and contain a minimum number of broken kernels . This article mainly introduce the rice milling machine ‘s development and how rice milling machine work.

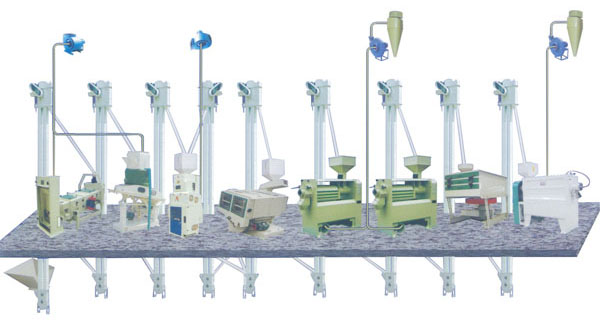

Rice mill processing line design

Rice mill processing line design

Rice milling is the process of removing the husk and bran layer to produce white rice. the rice milling machine ‘s development and how rice milling machine work can be undertaken as:

1) A one step milling process where the husk and the bran are removed in one pass and white rice is produced directly from the paddy.

2) A two-step process where the husk and the bran are removed separately, and brown rice is produced as an intermediate product.

3) A multistage process where rice passes through a number of different operations and machines from paddy to white rice.

Horizontal rice whitener

Horizontal rice whitener

The development of rice milling machine and how rice milling machine work:

The traditional rice milling machine work by manual.

One pass milling Pestle and mortar Hand pounding of paddy in a mortar wit a pestle is still practiced in some remote areas. Pounding the paddy induces upward and downward forces on grain against grain that removes the husk and some bran layers. Then use the steel single pass mill. This type of mill is still very popular in many of the poorer rice-growing countries and is widely used for custom milling of household rice. It is also still popular for milling parboiled rice in Bangladesh and many African countries. But this type mill with a lower yield of rice.

Two stage mills, Which mainly used for smaller capacity paddy processing.

Rice mill processing line

Rice mill processing line

The two-stage mill has separate hulling and polishing processes. Rubber rollers remove the husk and the brown rice is then polished with a steel friction whitener similar to the Engleberg. These mills have a capacity of between 0.5 to 1 ton per hour paddy input and are often used for custom milling in the rural areas. The milling performance of the compact rice mill is superior to the single pass Engleberg huller with milling recoveries normally above 60%.

Now , mostly of the rice milling machine is multiple pass rice milling, Which is also a commercial Mill

The milling process in larger commercial mills combines a number of operations that produces higher quality and higher yields of white rice from paddy or rough rice.

Rice polisher

Rice polisher

The rice milling machine working process involves:

1. Pre-cleaning the paddy prior to milling

2. Removing the husk or outer layer from the paddy

3. Rice milling section

4. Polishing or whiting the brown rice to remove the bran layer

5. Separating the broken grains from the whole kernels

6. Color Sorting

7. Bagging the milled rice

8. Managing the by-products,mainly for fuel of steam boiler or stove.

Advanced rice milling machine will improve the rice yield and decrease the broken rice rate, which is more and more popular by many developing countries, if you are in interested in rice milling machine, please contact us directly.