Rice mill manufacturing process

FAQ / Chat online / Technical support / Jun 03, 2019

High quality rice can be obtained by the following rice mill manufacturing process. We use a new generation of sand roller rice milling machine. The design is based on the concept of sand roller and iron roller. The iron roller is organically fused into the sanding roller, so that the rice is rubbed by the roller while being ground by the sanding roller, thereby realizing the organic parallel connection of the sand and the iron roller rice machine. Significant savings in processing time and cost. With a compact body, large "memory" features. Based on Africa's rice processing market, this machine can easily meet the high standards of the rice mill manufacturing process. It is compact and easy to operate. The whole machine is divided into the feeding part, the grinding part, the discharging part and the sucking part. The division of labor of each part is clear. The traditional rice milling machine has only a single sanding roller and iron roller or a simple tandem model of sand. The rice mill adopts a new design, so that the rice is rubbed by the iron roller while being ground by the sand roller.

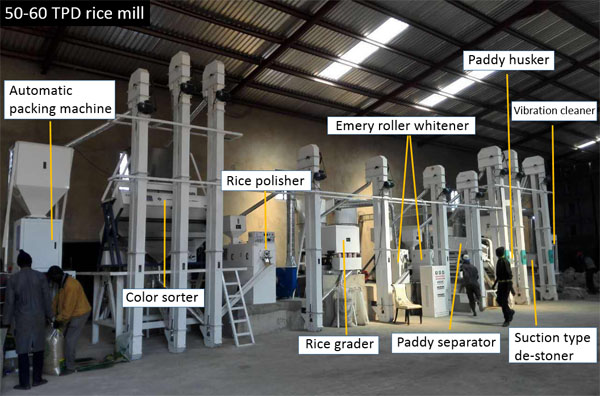

Main machines in rice mill factory

Main machines in rice mill factory

The entire processing process of the rice mill manufacturing process using this type of rice mill is 10%-30% lower than the other processes, and the whiteness is enhanced by 10-20%.

According to the performance of stone removal machine in the rice mill manufacturing process, there will be part of the rice in the stone discharged through the primary screening surface. This mixture of rice and stone is selected in the second selected sieve surface. The re-selected screen surface is equipped with a built-in fan to blow the stone, so that the stone and the rice are completely separated, and the stones are collected and discharged by the stone discharge port. The maintenance cost is low, the structure of the machine is firm, there is no need to add lubricating oil, the screen surface is punched by a stainless steel plate and the sieve body is easy to be pulled out for cleaning or replacement. The new structure is compact and has a small footprint. This is the needed part in the rice mill manufacturing process.

Produced rice

Produced rice

Follow the rules of the rice mill manufacturing process during the use of it, please pay attention to the safety requirements, and our rice milling equipment will be equipped with an operating manual, as well as an engineer to guide the installation, training workers to operate the machine correctly.

Prev: How rice milling machine work?

Next: Steps in rice milling