Rice milling system and steps

FAQ / Chat online / Technical support / May 08, 2019

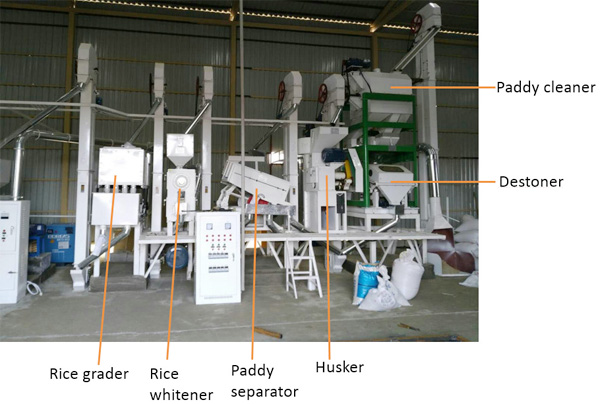

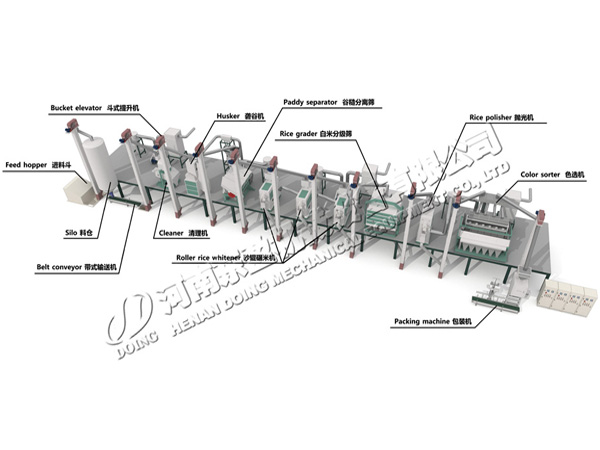

The rice milling system and steps for processing of high standard products include at least five parts.

The first step is for cleaning. Vibrating cleaning screen adopts new manufacturing process and materials, with high mechanical strength, wide applicability, good cleaning effect and large output. The cleaner is widely for rice milling system and steps.

Rice mill basic configuration

Rice mill basic configuration

The second step is for de-stone. The stone removal machine developed by Henan Doing Group separates stones and heavy impurities from the grain by utilizing the difference in specific gravity of the materials. Compared with the traditional screening method, this new type can separate stones and heavy impurities from the grain more effectively. The thicker steel plate and the sturdy support structure ensure that the machine is durable. This is to ensure the standard and quality of the product in the rice milling system and steps.

Rice milling system

Rice milling system

In the rice milling system and steps, the third step is husking. The rubber roller and the rice husk separator adopt a pair of rubber rollers with opposite rotation and different rotation speeds, so that the rice falling between the rubber rollers is peeled off by the line speed difference and shelled; the raw material after shelling enter the chaff separation The machine can completely separate the chaff in the raw material. The machine adopts automatic pneumatic control, which has the characteristics of high automation degree, easy adjustment, high and stable shelling rate and small vibration of the machine.

Large rice mill factory

Large rice mill factory

The fourth step is grain separation. The grain separator have the characteristics of high separation ability and simple maintenance. It separates the mixture of rice and brown rice into three forms: a mixture of rice brown rice. The rice is returned, then a mixture of rice and brown rice is sent in rice milling system and steps. In the feed inlet, only brown rice is sent to the rice mill, which increases the milling repetition rate and reduces the broken rice when using a low-pressure rice mill, so that pure rice without rice can be produced.

The fifth step is rice milling. The traditional sand roller rice machine only has the function of grinding, but it does not have the friction function, which leads to the increase of a large amount of broken rice during processing and increases the cost. Although the traditional iron roller rice machine has a friction function and has less broken rice during processing, the working principle of the iron roller rice machine determines that the surface layer of the rice is not easily removed, which affects the appearance.

For making better quality of finished product, most of our customer will equip the polisher and color sorter in the rice milling system and steps, so welcome your consultation.